How Scanning Electron Microscopy Can Help Developing Innovative Technologies and Materials?

Li-ion batteries and Electric Transportation

The challenges in developing eco-friendly vehicles necessitates to quickly switch to electric motors and decrease the weight of the vehicle. Our scientific and industrial collaborations, through the Industrial Research Chair obtained by Prof. Gauvin in 2018, allows to help the development of new anode/cathode materials for Li-ion batteries as well as designing new or improved alloys for the car industry. Our SEM, STEM and FIB instruments combined with our team expertise are of primary importance to successfully support this industry that keeps attention more and more with the global warming.

-

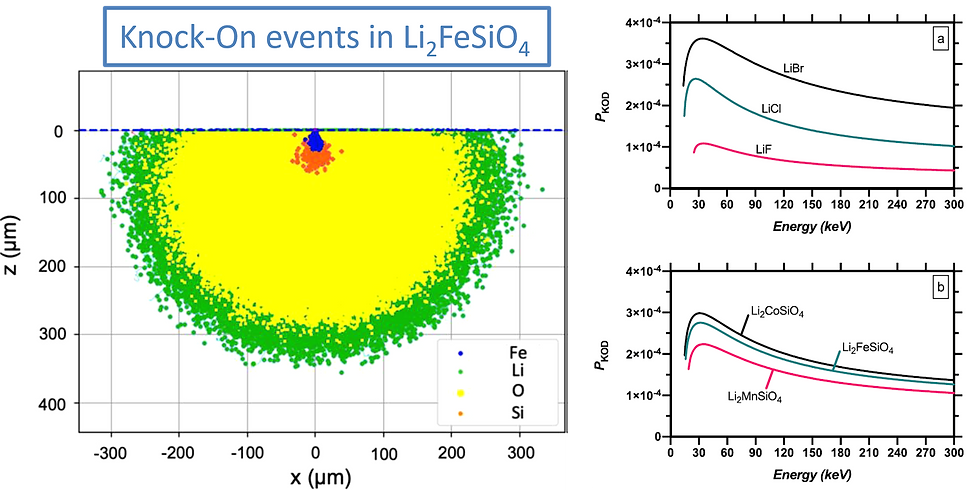

A. Jaberi, N. Brodusch, J. Song and R. Gauvin (2023), “Prediction of primary knock-on damage during electron microscopy characterization of lithium-containing materials”, Ultramicroscopy , Vol. 256, p. 113884.

-

I. Z. González, H. C. Chiu, R. Gauvin, G. P. Demopoulos and Y. Verde-Gómez (2022), “Silicon doped carbon nanotubes as high energy anode for lithium-ion batteries”, Materials Today Communications 30, 103158.

-

M. Golozar, H. Demers, A. Paolella, R. Gauvin and K. Zaghib, (2020). “Direct Li detection and microstructure evolution of Li° anode in all solid-state battery: in situ cycling SEM observation”, Microscopy and Microanalysis.

Publications

Nanomaterials and Catalysts

The development of smaller nanomaterials for improving energy transfer in solar cells and electric vehicle batteries as well as for maximizing catalytic conversion efficiency is the key to achieve carbon neutrality in a close future. At the MEMRG, we have a long-standing expertise in characterizing nanomaterials using our knowledge of low-voltage (transmission) scanning electron microscopy (SEM, STEM) to analyze their morphology, but also their chemical composition and crystallographic structure. Our SU-9000 SEM/STEM not only provides high spatial resolution imaging but also incredible EDS precision and EELS capabilities, an ideal combination to extract quality data from the specimens.

Mixed TiO2 (dark) and carbon black particles (bright grey) from a composite electrode for electrochemical energy storage in panel a at ELanding= 500 V in deceleration mode (E0= 2 kV) Source: N. Brodusch, H. Demers, M. Trudeau, R. Gauvin (2014), Surface and Interface Analysis. Published Online (Wiley Online Library) DOI 10.1002/sia.5584

-

Y. Verde-Gómez, E. Montiel-Macías, A. M. Valenzuela-Muñiz, I. Alonso-Lemus, M. Miki-Yoshida, K. Zaghib, N. Brodusch and R. Gauvin (2022), “Structural Study of Sulfur-Added Carbon Nanohorns”, Materials 15 (10), 3412.

-

A. Gellé, G. D. Price, F. Voisard, N. Brodusch, R. Gauvin, Z. Amara, and A. Moores (2021), “Enhancing Singlet Oxygen Photocatalysis with Plasmonic Nanoparticles”, ACS Applied Materials & Interfaces, 13, 30, pp. 35606 - 35616.

-

M. Rosales, J. Orive, R. Espinoza-González, R. F. de Luis, R. Gauvin, N. Brodusch, B. Rodríguez and F. Gracia (2021), “Evaluating the bi-functional capacity for arsenic photo-oxidation and adsorption on anatase TiO2 nanostructures with tunable morphology”, Chemical Engineering Journal, 415, 128906.

Publications

Metallurgy and Coatings

As part of the Mining & Materials Engineering Department, we strongly interact with other research groups in the department involved in the development of new alloys and surface coatings. We also cultivate strong relationships with other universities as well as industrial partners to improve the knowledge of existing/new alloys and characterize the microstructures inherent to thermal and cold-spray processing. Our expertise in this field involves a pertinent use of low voltage SEM/STEM imaging, EBSD/CBED and spectroscopic techniques (EDS/EELS). To improve statistical accuracy, we make use of deep learning segmentation and automatic image acquisition.

Nanotwins in a cold sprayed copper coating. E0 was 30 kV. Source: N. Brodusch, H. Demers, M. Trudeau, R. Gauvin (2014), Surface and Interface Analysis. Published Online (Wiley Online Library) DOI 10.1002/sia.5584

-

C. C. Bortolan, L. C. Campanelli, P. Mengucci, G. Barucca, N. Giguère, N. Brodusch, C. Paternoster, C. Bolfarini, R. Gauvin and D. Mantovani (2022) “Development of Ti-Mo-Fe alloys combining different plastic deformation mechanisms for improved strength-ductility trade-off and high work hardening rate ”, Journal of Alloys and Compounds, 925, 166757.

-

N. Brodusch, S. V. Brahimi, E. Barbosa De Melo, J. Song, S. Yue, N. Piché and R. Gauvin (2021), “Scanning Electron Microscopy versus Transmission Electron Microscopy for Material Characterization: A Comparative Study on High-Strength Steels”, Scanning, 5511618.

-

Y. Zhang, N. Brodusch, S. Descartes, R. R. Chromik and R. Gauvin (2014), “Microstructure Refinement of Cold-Sprayed Copper Investigated By Electron Channelling Contrast Imaging”, Microscopy and Microanalysis, Vol. 20 , No. 05, pp. 1499 – 1506

Publications

Mining and Geology

As part of the Mining and Materials Engineering Department, MEMRG acts in support to the development of the mining industry to improve extraction efficiency and quality to reduce its impact on the environment. In relation to the lithium-ion battery research growing in Canada and Québec, our research staff and students are involved in helping this industry to become a international leader regarding lithium extraction and recycling.

Brucker Flat Quad XFlash 5060F (BFQ) 400S, 1200 X 960, 0.325 mSpixel

-

N. Brodusch and R. Gauvin (2022), “Phase Differentiation based on x-ray energy spectrum correlation with an energy dispersive spectrometer (EDS) ”, Ultramicroscopy, 238, 113534.

-

C. Teng and R. Gauvin (2020), “Multivariate Statistical Analysis on a SEM/EDS Phase Map of Rare Earth Minerals”, Scanning, Article ID 2134516, 11 pages.

-

Jordens, C. Marion, R. Langlois, T. Grammatikopoulos, R. S. Sheridan, R. Gauvin and K. Waters (2016), “Beneficiation of the Nechalacho rare earth deposit. Part 2: Characterisation of products from gravity and magnetic separation”, Minerals Engineering, 99, pp. 96-110

Publications

Life Science and Biological Applications

Although this is not our field of expertise, our high resolution SEM and STEM equipment proved to supply high quality imaging and spectroscopic data that can reveal surface and internal details from a wide variety of samples.